Robotic welding allows manufacturers to enjoy higher product yields and throughput while saving money on labor and inventory.

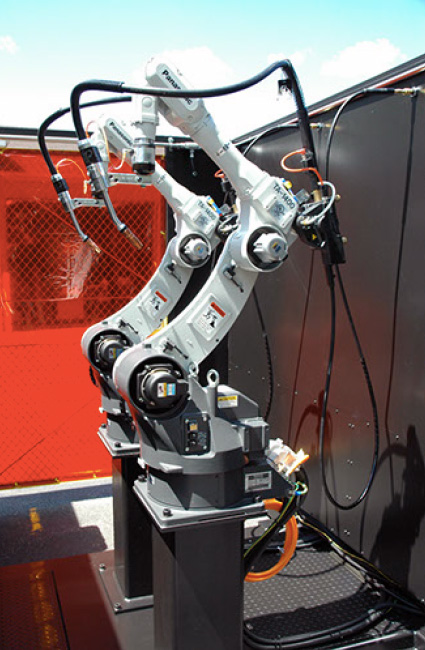

With the right training, anyone can learn to easily program a robot to perform precise, consistent welds time and time again, reducing waste and production time. Weld-Action has installed hundreds of robots into work cells, resulting in increased production and lower costs for all of our customers. We specialize in six-axis, servo-driven robots that have a repeatability of eight one-thousandths of an inch. Robot controls also control safety, peripheral equipment, power, positioning equipment, torch cleaning, adaptive control sensing, quality control functions, and weld parameters.

Robotic Welding features include:

- Multi-purpose programming with positions stored in memory

- Teach pendant with a point-to-point method

- MIG, TIG, plasma arc, spot weld processes/equipment

- Servo or indexing-type positioner

- Customized work-holding fixtures

- Safety equipment

- Common underframe

- Protective fencing

- Main Programmable Logic Controller (PLC) cabinet

- Accessories:

- Torch cleaning

- Tip replacement